Aluminum anodes protect offshore platforms and hulls

Aluminum anodes provide efficient anti-corrosion protection for offshore platforms and hulls through electrochemical principles. The core principle is that aluminum anodes, as negative electrodes, corrode and dissolve preferentially, releasing electrons to make the protected steel structure (offshore platform/hull) the cathode, thereby inhibiting the corrosion reaction of steel.

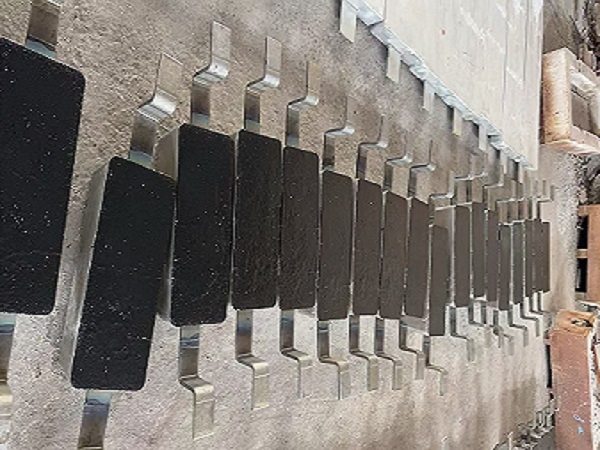

1. Protection of offshore platform jackets and pile legs

Aluminum anodes are welded on the surface of steel piles in the full immersion area to resist seawater erosion by continuously releasing current. For example, the life of the Bohai Oilfield platform is extended to more than 20 years after installation, and the corrosion rate of the steel structure is reduced by 60%.

----Technical points: Al-Zn-In alloys are used (potential is stable at -1.0V to -1.1V vs Ag/AgCl), and the power generation per unit weight is 3 times that of zinc anodes.

2. Protection of hulls and ballast tanks

Aluminum anodes are evenly arranged on the bottom and side of the ship, and the inner wall of the ballast tank is customized with a curved anode bonding structure. Its density is only 2.7g/cm³ (1/3 of zinc anode), which reduces the weight of the ship and improves fuel efficiency, and the maintenance cycle is extended to 5 years.

In normal times, the cathodic protection system should be regularly inspected, including the remaining weight, potential and other parameters of the anode, so that the failed anode can be replaced in time.

If you have any project needs aluminum anode, please feel free to contact us. Decho Metal will provide high quality anode for you.